A slip ring is an electromechanical device that connects a fixed to a rotating system. It is made use of in applications where energy or electrical signals must be transmitted while rotating. Slip rings are also known as electrical rotary seals, rotary connectors, or electrical seals. It is to improve mechanical performance and simplify operation in a variety of electric machines.

Whenever a device rotates for a predetermined number of revolutions, you can use a long enough power cord. But it’s a complicated setup, and that is impossible if the components are constantly running. For this type of application, this configuration is neither practical nor reliable.

Types of Slip Rings:

Nowadays, almost every product has a slip ring. Slip rings, high-speed slip rings, electrically conductive disc slip rings, and many other types of slip rings at https://www.grandslipring.com/ are available on the market. It has a distinct purpose and application Slip rings are of various types based on their design and size. The numerous kinds of slip rings are described below.

Wireless Slip ring:

The use of carbon and metal resistance contact brushes in slip rings should not be based on approved procedures. Alternatively, they rely on the electromagnetic field to transform data and wireless energy. Its design is with coils in a rotating receiver and a stationary receiver. They are known as the best complement to traditional slip rings because they are easy to store and withstand harsh environments.

Pancake slip ring:

The conductors in this type of slip ring are on a flat disc. This type of concentric disc is in the center of a rotating axis. This slide has a flat shape. As a result, it is also known as a slip ring or slip ring. The axial length will get reduced as a result. As a result, this type of slip ring is for space-constrained applications. This arrangement is heavier and has more volume. It has a higher capacity and a longer brush life.

Mercury contact Slip ring:

The mercury contact slip ring serves as a conductive medium in this type. It can transfer electrical and current signals through liquid metal under normal temperature conditions. It also provides the most scientifically sound and cost-effective solution for industrial applications. However, the use of mercury creates a safety issue because it is a poisonous substance. This type of slip ring is helpful in applications such as food and pharmaceutical manufacturing, or the processing is hazardous. In the event of a mercury leak, this could cause damage to the product.

Ethernet slip ring:

This type of slip ring provides dependable products that enable Ethernet protocol transfer via a rotary system. Three vital parameters are when selecting an Ethernet slip ring for communication: Return Loss, Insertion Loss, and Crosstalk Ethernet header loops designed to meet impedance matching, loss reduction, and crosstalk control requirements.

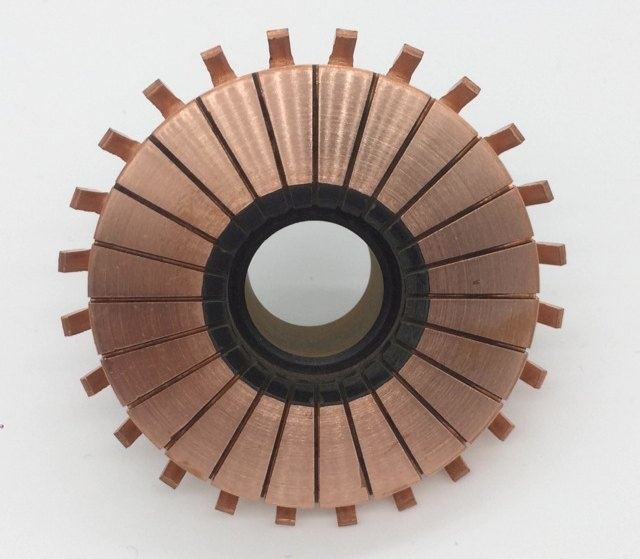

Through-Hole Slip ring:

A hole is in the center of this type of slip ring. It is helpful in devices that require 360-degree rotation to transmit power or a signal. This type of slip ring is for use with a flange on sleeve support. It has enough free space in the center to connect the shaft of a car without interfering with the cable’s rotation. It has a long lifespan, is low-noise, and requires little maintenance. This rotary joint is used to build pneumatic passages and can be with high-frequency joints.