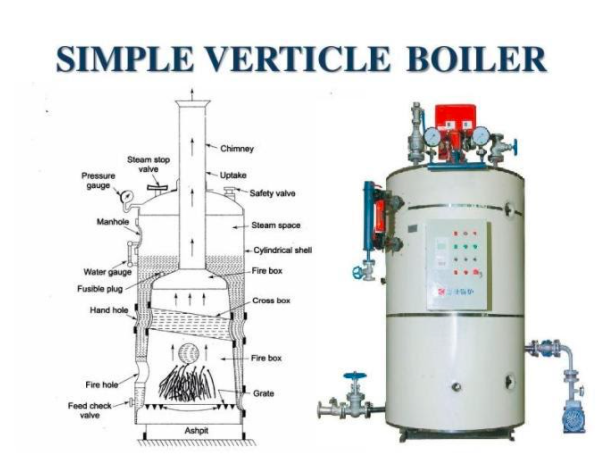

A vertical boiler is a small boiler that uses to produce steam for small machines. This boiler has many fire tubes installed in a horizontal direction.

The vertical boilers are most commonly used as donkey boilers for boats. The vertical boiler consists of centrifugal pump, a shell, manhole, chimney, fire tubes and a furnace.

Types of Vertical Boilers

The vertical boiler has the following major types:

1) Cochran boiler

This boiler is a most commonly used boiler in the marine applications. It can be burned directly using coal or petroleum-based fuels. It can also be used to recover heat from the exhaust gases of large diesel engines. This type of boiler is called a composite boiler if it can be heated with the exhaust gases from the main propulsion system or it can be burned separately in the port (usually with oil instead of coal).

The Cochran boiler has a vertical cylinder with a hemispherical domed top. The shape of this dome is strong enough that you don’t have to stay around. The combustion chamber also has a hemispherical dome that rivet with the base ring to provide less space for water.

Fire pipes are laid on top in a single horizontal group and installed between two flat vertical plates inserted into the cylinder of the boiler. The combustion chamber has the shape of a “dry back” and instead of a water jacket it is surrounded by steel sheets and firebricks. Exhaust gas from the fire tubes enters the external smoke chamber and vertical smoke duct. A manhole is provided on the hemispherical dome to repair the pipe.

There are several possible arrangements for heating the gas for combined combustion. In most cases, another dry combustion chamber uses a bidirectional tube arrangement that transports gas from one tube bundle to another. Some arrangements use a separate tube bundle for heat recovery from the exhaust gas or for direct combustion of the gas, while others direct the exhaust gas into the top of the combustion chamber (not ignited). Pure waste heat boilers may not have a combustion chamber, with the exception of a flat dome-shaped plate for added strength.

2) Clarke Chapman boiler

This vertical boiler is similar to the Cochrane type, except that the top of the Clarke chapman boiler is more of a flat dome than a hemisphere. This dome shape is strong enough to withstand pressure, but there is a sharp angle between the case and the top plate. This corner requires gusset support.

These boilers are available in two formats: ” Wetback ” and ” Dryback”. The wetback or “dry back” combustion chamber (pictured) is completely surrounded by water. This increases the heating surface and reduces heat loss, but makes the boiler more difficult to manufacture and makes it difficult to clean the pipes.

3) Blake boiler

This vertical boiler has chrematistics of both Robertson and Clarke Chapman designs. All combustion chambers are in water spaces, have a heating surface, and are cylindrical for added strength. The tubes are arranged radially rather than parallel so that they enter the combustion chamber vertically. This simplifies the final stretching process and improves the seal. The smoke chamber is relatively large and is partially wrapped around the outside of the boiler drum.

click here for more articles